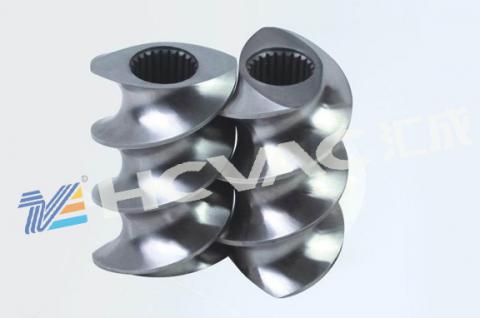

Screw Compressor Vacuum Coating Machine hard coating can protect thehigh stress hydraulic components of the machine from abrasion, adhesion, corrosion, and deformation.In the case of high pressure, high flow rate and high speed,low flammable, based on the aqueous liquid medium (HFA, HFC), poor lubrication, it can still ensuring reliable operation.

The vacuum sealing of chamber and the interior design and material of moving parts are under consideration of high-temperature bear, assembling high efficiency roundness arc evaporation source or rectangular flat arc evaporation source. We can also install hollow cathode gun and impact resistance bias power supply, to ensure the density and reactivity of plasma, increase the compactness and adhesion of coatings. Substrates can be three-dimensional motion, to enhance the uniform of coating. The full automatic control processing is steady and perfect.

It can deposit TiN,TiC,TiCN,TiAlCN,TiCrN,TiCrCN,TiAlCrN, multilayer super hard coatings.

| HCSH-380 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 2pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 3-5hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS Plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=864 D10×75mm=264 Insert D18×5mm=1440 Hobs D80×80mm=15 |

|

| HCSH-600 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 2pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 4-6hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS HCD plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=1920 D10×75mm=512 Insert D18×5mm=3276 Hobs D80×80mm=40 |

|

| HCSH-650 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 4pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 3-6hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS Plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=4032 D10×75mm=880 Insert D18×5mm=6400 Hobs D80×80mm=64 |

|

| HCSH-900 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 6pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 5-8hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS Plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=8640 D10×75mm=2200 Insert D18×5mm=1200 Hobs D80×80mm=140 |

| Type | name | colour | coating | Micro hardness (HV0.05) |

Max. Usage temperature (℃) |

Friction- (fretting) coefficient |

Thickness (um) |

| Nitrogen ceramics |

HAL | Black | ALTiN | 3800 | 900 | 0.6 | 2.5±0.5 |

| HAL Plus | Black | ALTiN | 3800 | 900 | 0.6 | 4±0.5 | |

| HAL Mini | Black | ALTiN | 3500 | 900 | 0.6 | 1.5±0.5 | |

| HAL B | Atropurpureus | ALTiN | 3600 | 900 | 0.6 | 2.5±0.5 | |

| HAR | Silver | CrN | 2000 | 700 | 0.3 | 3±0.5 | |

| HAT | Golden | TiN | 2400 | 600 | 0.5 | 3±0.5 | |

| HAS | Bronze | AlTiSiN | 3800 | 1000 | 0.4 | 3±0.5 | |

| HATC | Gray | TICN | 3500 | 400 | 0.2 | 2±0.5 | |

| HATC Plus | Bronze | TICN | 3200 | 400 | 0.25 | 2±0.5 | |

| HART | Golden | CrTiN | 2500 | 600 | 0.4 | 2.5±0.5 | |

| HRA | Blue grey | AlCrN | 3500 | 1000 | 0.4 | 4±0.5 | |

| HRAT | Gray | AlTiCrN | 3200 | 900 | 0.4 | 3±0.5 | |

| DLC | HCC | Black | CrN+W-C:H | 2200 | 300 | 0.2 | 2±0.5 |

| HCMC | Black | Cr+W-C:H+DLC | 1800 | 300 | 0.1 | 2±0.5 |

| Name | Low alloy steel |

High alloy steel |

Stainless |

Cast iron |

Copper | Bronze | Si<12% Al alloy |

Si>12% Al alloy |

Wood | Plastic | Drill | Drill cutting |

EndMill | Milling tool |

Turnin insert |

Hob | Slottin cutter |

Hob slottin cutter |

Tap |

| HAL Plus | A- | A | A- | A | A | A | A- | A | A | A | A | ||||||||

| HAL Mini | A- | A | A | A | A- | ||||||||||||||

| HAL B | A- | A | A- | A | A- | A- | A | A- | A- | ||||||||||

| HAR | A | A | A | A | A- | ||||||||||||||

| HAT | A | A | A | A- | A- | A- | A- | A- | A- | A- | A- | A- | |||||||

| HAS | A- | A- | A | A | A | A | |||||||||||||

| HATC | A | A | A- | ||||||||||||||||

| HATC Plus | A | A | A- | A | |||||||||||||||

| HART | A | A- | A- | A- | A- | A | A | A | A | A | A- | A- | A- | A- | A- | ||||

| HRA | A- | A | A | A- | A- | A- | A- | A- | A- | A- | A- | A- | A- | A- | A- | ||||

| HRAT | A | A | A | A- | A- | A- | A- | A- | A- | A- | A | A | A | A | A | A | A | A | |

| HCC | A | A | A- | A | A | A | |||||||||||||

| HCMC | A | A | A- | A | A | A- | |||||||||||||

| A:Applicable of existing materials or processing environment | |||||||||||||||||||

| A-:Can be used in the materiial and processing environment | |||||||||||||||||||

Radial piston motor , axial piston pumps, vane pumps, screw pumps.