This machine is equipped with multi-hollow cathode guns, which adopts hollow cathode effect of glow discharge within tantalum tube, lead to the tantalum tube heated to incandescence then emission electron strongly and arc discharge, at the same time, come into be a high-density plasma electron flow, and flow into target then make it evaporate, vaporization, ionization(or effected by reactive gas)coating on substrates. There is special jigs for substrates installed in the machine, which can make substrates rotation themselves, with PID temperature controller, temperature control accuracy is ±1℃.

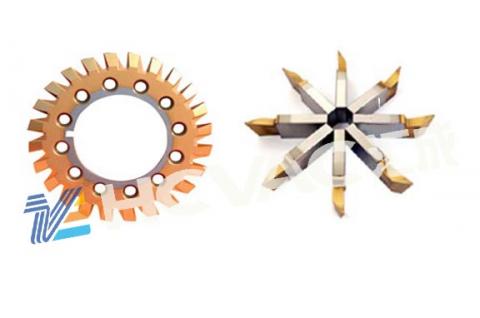

The concentration of hollow cathode plasma ion is high, high ionization rate, the deposited film is with a good adhesion, bright color. It is special used for hard coatings on tools and moulds, and decorative coatings too, such as TiN,TiCN, TiC, etc.

| HCSH-380 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 2pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 3-5hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS Plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=864 D10×75mm=264 Insert D18×5mm=1440 Hobs D80×80mm=15 |

|

| HCSH-600 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 2pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 4-6hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS HCD plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=1920 D10×75mm=512 Insert D18×5mm=3276 Hobs D80×80mm=40 |

|

| HCSH-650 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 4pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 3-6hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS Plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=4032 D10×75mm=880 Insert D18×5mm=6400 Hobs D80×80mm=64 |

|

| HCSH-900 | Usable plasma volume | Application technology | target |

| Ø400x H450mm | CMARC | 6pcs×3 | |

| Production cycle | Standard coating | Custom coating | |

| 5-8hours/cycle | TiN,CrN,AlTiN,AlCrN | TiCN,TiAlCrN,TiAlSiN , DLC | |

| Hardware | Software | Production/batch | |

| Magnetic molecular pump Pulse BIAS supply / HIPIMS Plasma etching |

Industrial PLC system Industrial PC system HCVACExpert remote diagnosis system |

EndMills D4×50mm=8640 D10×75mm=2200 Insert D18×5mm=1200 Hobs D80×80mm=140 |

| Type | name | colour | coating | Micro hardness (HV0.05) |

Max. Usage temperature (℃) |

Friction- (fretting) coefficient |

Thickness (um) |

| Nitrogen ceramics |

HAL | Black | ALTiN | 3800 | 900 | 0.6 | 2.5±0.5 |

| HAL Plus | Black | ALTiN | 3800 | 900 | 0.6 | 4±0.5 | |

| HAL Mini | Black | ALTiN | 3500 | 900 | 0.6 | 1.5±0.5 | |

| HAL B | Atropurpureus | ALTiN | 3600 | 900 | 0.6 | 2.5±0.5 | |

| HAR | Silver | CrN | 2000 | 700 | 0.3 | 3±0.5 | |

| HAT | Golden | TiN | 2400 | 600 | 0.5 | 3±0.5 | |

| HAS | Bronze | AlTiSiN | 3800 | 1000 | 0.4 | 3±0.5 | |

| HATC | Gray | TICN | 3500 | 400 | 0.2 | 2±0.5 | |

| HATC Plus | Bronze | TICN | 3200 | 400 | 0.25 | 2±0.5 | |

| HART | Golden | CrTiN | 2500 | 600 | 0.4 | 2.5±0.5 | |

| HRA | Blue grey | AlCrN | 3500 | 1000 | 0.4 | 4±0.5 | |

| HRAT | Gray | AlTiCrN | 3200 | 900 | 0.4 | 3±0.5 | |

| DLC | HCC | Black | CrN+W-C:H | 2200 | 300 | 0.2 | 2±0.5 |

| HCMC | Black | Cr+W-C:H+DLC | 1800 | 300 | 0.1 | 2±0.5 |

| Name | Low alloy steel |

High alloy steel |

Stainless |

Cast iron |

Copper | Bronze | Si<12% Al alloy |

Si>12% Al alloy |

Wood | Plastic | Drill | Drill cutting |

EndMill | Milling tool |

Turnin insert |

Hob | Slottin cutter |

Hob slottin cutter |

Tap |

| HAL Plus | A- | A | A- | A | A | A | A- | A | A | A | A | ||||||||

| HAL Mini | A- | A | A | A | A- | ||||||||||||||

| HAL B | A- | A | A- | A | A- | A- | A | A- | A- | ||||||||||

| HAR | A | A | A | A | A- | ||||||||||||||

| HAT | A | A | A | A- | A- | A- | A- | A- | A- | A- | A- | A- | |||||||

| HAS | A- | A- | A | A | A | A | |||||||||||||

| HATC | A | A | A- | ||||||||||||||||

| HATC Plus | A | A | A- | A | |||||||||||||||

| HART | A | A- | A- | A- | A- | A | A | A | A | A | A- | A- | A- | A- | A- | ||||

| HRA | A- | A | A | A- | A- | A- | A- | A- | A- | A- | A- | A- | A- | A- | A- | ||||

| HRAT | A | A | A | A- | A- | A- | A- | A- | A- | A- | A | A | A | A | A | A | A | A | |

| HCC | A | A | A- | A | A | A | |||||||||||||

| HCMC | A | A | A- | A | A | A- | |||||||||||||

| A:Applicable of existing materials or processing environment | |||||||||||||||||||

| A-:Can be used in the materiial and processing environment | |||||||||||||||||||

Suitable for tools and mold hard coating, also can be used for the decorative coating of other hardware.