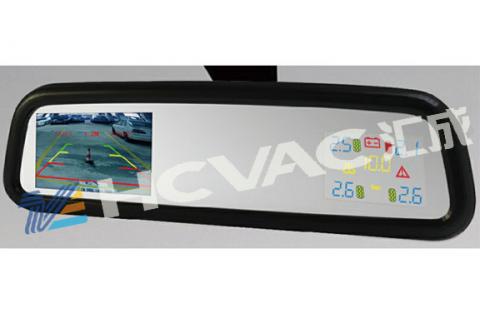

Anti -glare rearview mirror vacuum coating machine with anti-glare coating technology after the glass plated on non-reflective transparent film, can inhibit the light reflection reaches as high as 99%, using the rear view mirror the equipment production can be achieved in the automobile to start immediately after the opening of anti-glare function, automatic detection of environmental light function, and can be identified according to the intensity of light vehicle after irradiation, when the ambient light is lower than the set value, and the rear light intensity is higher than the set value, the rearview mirror automatic start, immediately by total reflection state transform into Anti-Glare condition of dark green, light after the reflection in the mirror after not dazzling, to achieve the effect of electro chromic.

| Vacuum chamber dimensions | 430×1000mm | 540×1000mm | 700×1200mm | 430×1000mm | 540×1500mm |

|

The type of power |

DC power supply, AC power, RF power, pulse DC power supply |

||||

|

Vacuum chamber structure |

Vertical double door, vertical, horizontal, single door single door pumping system |

||||

| The vacuum system |

KT800/ molecular pump mechanical pump +630 mechanical pump +1200 +4400 roots pump x2 |

||||

| Vacuum range | 5×10-6 ~1.5 x10-4 mbar | ||||

| Pumping time |

The no-load air pumped to 5 × 10-2Pa less than 6 minutes |

||||

| Control mode |

Manual and semi-automatic and fully automatic integration / touch screen PLC |

||||

| Remarks |

The vacuum chamber size can be customized according to customer products and special process requirements |

||||

Automobile rearview mirror, comprising a central rearview mirror, the left rearview mirror, right rearview mirror.