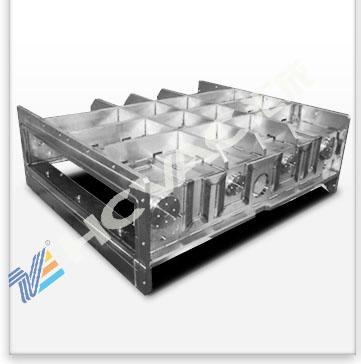

Continuous (In-line) equipment, its chamber geometry mostly rectangular, in accordance with the substrate transmission range, it can be divided into vertical and horizontal. according to the visual process demand, the valve device can be a separate among chambers. Continuous chamber that applies into some fields: anti-electromagnetic wave interference (Anti-EMI) coating equipment, decorative surface coating (SDC) equipment, Touch-panel coating equipment, Thin film solar cell coating equipment, Low-E glass coating equipment.

Advantages:

1. Vacuum parts manufacturing, a variety of specifications of the vacuum parts inventory for the use of chamber manufacturing;

2. Processing capacity and complete facilities, our company can complete a set of process: plate cutting, machining, welding, cleaning, assembling and leak engineering;

3. Taking advanced 3D design software to facilitate communication with customers and on-site processing;

4. HCVAC Vacuum Technology, equipped with a professioal vacuum pump maintenace team, can quickly facilite large-size vacuum chamber with pumping process and leak operation.