Color stainless steel pipe coating equipment, with properties of safety, environmental protection, process stability, various colors, wear resistance, corrosion resistance, high temperature resistance, good adhesion and not easy to fade.

Color surface layer has strong corrosion resistance, high mechanical performance, prolonged no-fading, color with light irradiation angle in different colors changing characteristics, better ability to 200 ℃ temperature resistance, salty fog corrosion resistance than stainless steel, colored stainless steel plate, wear resistance and scratching resistance performance are equivalent to the performance of foil layer in gold coatings.

Coated colors:

Titanium gold, champagne gold, pale bronze, Japan gold, zirconium gold, rose gold, rose red, bronze, copper, black ash, black, purple, dark brown, sapphire blue, dark brown, dazzle color, stainless steel color, coffee color.

Applications:

Elevator decoration, Stars Hotel, luxury villas, high-end brand stores, KTV, furniture, decoration and other large shopping malls.

Such as: anti-theft doors and windows, railings, stair railings, outdoor construction, curtain nets stand, clothes bar, exhibition hall bracket, etc..

Standard for color stainless steel pipe(mm)

| 8×0.5~1.2 | 22×1.0~6.0 | 73×1.2~6.0 |

| 9.5×0.5~1.5 | 23×1.0~6.0 | 76.2×1.2~6.0 |

| 12.7×0.5~1.5 | 25.4×1.0~6.0 | 88.9×1.2~6.0 |

| 14.5×0.9~2.0 | 29×1.0~6.0 | 101.6×1.2~6.0 |

| 15.9×1.0~2.0 | 31.8×1.0×6.0 | 108×1.2~6.0 |

| 17.2×1.0~2.0 | 42×1.0~6.0 | 114×1.2~6.0 |

| 18×1.0~2.0 | 48×1.0~6.0 | 127×1.2~6.0 |

| 19.1×1.0~2.0 | 50.8×1.0~6.0 | 133×1.2~6.0 |

| 20.2×1.0~2.0 | 60×1.0~6.0 | 141×1.2~6.0 |

| 21×1.0~2.0 | 63.2×1.0~6.0 | 152×1.2~6.0 |

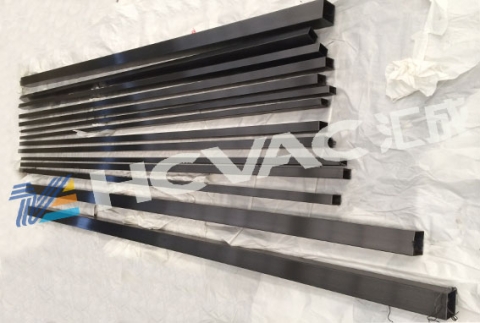

Standard for color stainless steel pipe(mm)

| 10×10×0.8~1.0 | 35×35×1.0~6.0 | 50×20×1.0~6.0 |

| 12×12×0.8~1.5 | 38×38×1.0~6.0 | 50×25×1.0~6.0 |

| 15×15×0.8~1.5 | 40×40×1.0~6.0 | 60×15×1.0~6.0 |

| 17×17×0.8~1.5 | 50×50×1.0~6.0 | 60×30×1.0~6.0 |

| 18×18×0.8~2.0 | 60×60×1.0~6.0 | 60×40×1.0~6.0 |

| 19×19×0.8~2.0 | 70×70×1.0~6.0 | 80×40×1.0~6.0 |

| 20×20×1.0~2.5 | 80×80×1.0~6.0 | 80×60×1.0~6.0 |

| 22×22×1.0~2.5 | 100×100×1.0~6.0 | 100×40×1.0~6.0 |

| 23×23×1.0~2.5 | 20×10×1.0~6.5 | 100×50×1.0~6.0 |

| 24×24×1.0~2.5 | 24×12×1.0~6.5 | 100×60×1.0~6.0 |

| 25×25×1.0~2.5 | 30×15×1.0~6.5 | 120×40×1.2~6.0 |

| 28×28×1.0~2.5 | 40×20×1.0~6.5 | 120×60×1.2~6.0 |

| 30×30×1.0~6.0 | 40×30×1.0~6.5 | 150×100×1.2~6.0 |

|

Mode |

HCCA-1800 |

HCCA-2000 |

HCCA-3000 |

HCCA-2000 |

HCCA-3000 |

HCCA-4000 |

HCCA-5000 |

|

Vacuum chamber dimension |

φ1800x2000 |

φ2000x2000 |

φ3000x3000 |

φ2000x6000 |

φ3000x6000 |

φ4000x8000 |

φ5000x10000 |

|

Vacuum system |

Mechanical pump+Roots pump+diffusion pump/Turbo molecular pump+holding pump |

||||||

|

Coating system |

arc evaporation source,coating auxiliary ion dedicated power supply |

||||||

|

Inflation system |

Mass flow meter |

Mass flow meter |

Mass flow meter |

Mass flow meter |

Mass flow meter |

Mass flow meter |

Mass flow meter |

|

Control mode |

Manual or automatic |

Manual or automatic |

Manual or automatic |

Manual or automatic |

Manual or automatic |

Manual or automatic |

Manual or automatic |

|

Ultimate vacuum |

5.0x10-4Pa |

5.0x10-4Pa |

5.0x10-4Pa |

5.0x10-4Pa |

5.0x10-4Pa |

5.0x10-4Pa |

5.0x10-4Pa |

|

Remark |

Above machine parameters for your reference only, specific according to customers' special requirement of practical process design. |

||||||