Suspension roll to roll vacuum coating machine equips with square or circular vacuum chamber, used in food packaging film, medical packaging films, cigarette aluminized transfer metallized paper, laser anti-counterfeit, gilding, with high-speed, efficient, stable and reliable characteristics.

Roll to roll system:

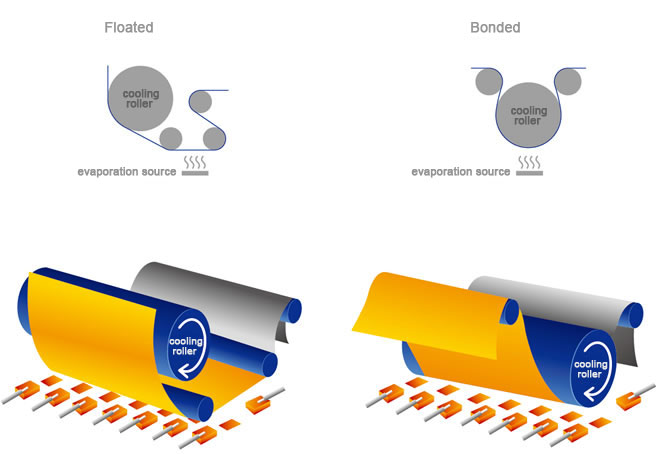

1,An innovative suspension coating design, rapid change volume, easier to maintain;

2, multi-level flattening system, coating is smoother, higher quality;

3, double cold drum design, better cooling, coating temperature is much lower, speed is faster, up to 1000 m / min.

Aluminum evaporation system:

1, top-mounted evaporation source structure, staggered, uniform evaporation, improve evaporation rates , you can quickly change the boat, easy to clean;

2, highly reliable evaporation system designed to minimize the failure rate;

3, Step wire system to ensure uniformity of the coating.

Control System:

1, Siemens integrated control system, bus, HMI, PLC control;

2, high-precision AC servo motor drive, four-roll four constant tension winding motor, control is more stable;

3, high-precision digital frequency regulation evaporation control;

4, aluminum wire stepper drive control system, more stable, more accurate;

5, the unique roller system monitoring technology.

Vacuum System:

1, use frequency control, large pump suction system, pumping faster, more energy-efficient;

2, double cold trap configurations, suitable for any climate.

Origin, wire feed system:

Features:

1,An innovative suspension coating designed to save more time of changing lap and cleaning for the coating production;

2, the world's leading coating speed, unparalleled efficiency, increase capacity by 50-80%;

3, the real non-plated empty lines, endless lines, wrinkles, and aluminum slag splashing, no pollution;

4, a more uniform coating, and better cooling effect, minimum thermal deformation of the film, the surface tension is not reduced;

5, especially for low-tension film CPP, PE, BOPP etc.

| Max width size | 1350mm | 1700mm | 2100mm | 2500mm | 2900mm |

| Max roled dia | 800mm | 800mm | 1000mm | 1000mm | 1000mm |

| Evaporation boat | 14 pieces | 18 pieces | 22 pieces | 26 pieces | 30 pieces |

| Evaporation pressure | 4x10-2pa(4×10-4mbar) | ||||

| Water recirculation rate | 25m3/h | 30m3/h | 35m3/h | 40m3/h | 45m3/h |

| Average Electrical Power Rating | 200KW | 230KW | 280KW | 300KW | 330KW |

| Winding strip | PET:8-35; CPP:18-60; BOPP PVC:15-60;(µm) | ||||

| Max winding speed | 720m/min | 1000m/min | |||

|

Monthly output |

250T | 330T | 480T | 580T | 680T |

| Control mode | Manual, semi-automatic and fully automatic integration/touch screen + PLC | ||||

| Remark | Vacuum chamber size can be customized according to the requirements of customers products and special process | ||||

For BOPP, PET, PVC, PE, CPP and other vacuum aluminum, metallized paper, aluminum and other non-woven products

widely used in tobacco, food, pharmaceutical, labels, daily necessities, gifts, Christmas pull flower printing and packaging industry and other fields, such as

PET twist

VMPET aluminum twist

VMCPP aluminized

PET film

VMPET matt aluminum

PET film special film

PET packaging films

PET pipe aluminized

PVC film aluminized

PC

PET film

PET

release film coated with adhesive film color film

brushed aluminized mylar film

aluminum cast polypropylene film aluminum bi

oriented polypropylene film aluminized polyethylene film

laser packaging composite film PET film laser laser transfer film

laser laser PVC OPP film laser stamping foil membrane

PPR

counterfeit trademarks