The HCVAC is an inline coating system based on our proprietary large-area coating technology. As the coater us very wide and can therefore process many substrates at the same time, it i9s especially suited for high productivity applications at very low costs. It is suited for large-area glass substrates.

It is the perfect choice for customer looking for highly productive and flexible production equipment combined with proven technology and design. Due to its large width, the productivity of the tool is exceptioally high while the process utilization is brought to a maximum. Thus, the HCVAC offers best cost of ownership by providing applicable economy of scale.

The process chamber can be equipped with five or more different prcess stations in a sputter down arrangement. It enables simultaneous processing of different material compositions from metallic and ceramic targets.

|

Target |

Material: metal, ceramics Utilization: planar > 30% rotable > 80% |

|

Substrate |

Material: glass Dimension(L×W), max.: 2000 × 2400mm Thickness: 1.8mm(1.4mm) to 4mm for glass |

|

Deposition System |

Deposition type: DC, pulsed DC, AC Magnetron type: planar, single or dual rotable Sputter arrangement: sputter dowm Substrate temperature range: RT/200℃/400℃ Substrate potential: floating Number of independent process gases: up to 4(Ar, O2 , N2 ,X) |

|

Transport |

Type of transport: inline Orientation of substrate during deposition: horizontal, LEL, SEL Conveyor speed, max.: ≦3.5 m/min(process); ≦30 m/min(handling) Throughput, max.: < 800 m2/h |

|

Cleaning of magnetron chambers |

Cleaning principle: mechanical exchange of shields Cleaning cycle: 7 to 28 days, depending on configuration

|

|

Utilities&supply |

Phase: 3 phases Voltage: 230V, 400V, 480V Frequency: 50 Hz to 60 Hz Power consumption: depending on configuration Cooling system: separate cooling circuit with heat exchanger Cooling supply: primary cooling water supply by customer Venting medium: compressed dry air or N2 Process gas: central supply by customer or local by gas cabinet |

|

System control &software |

Computer hardware: PLC, siemens S7 |

|

System dimensions |

Total system size(L×W×H): min. 20 m ×16.5 m ×3.5 m Total system wenght: depending on configuration |

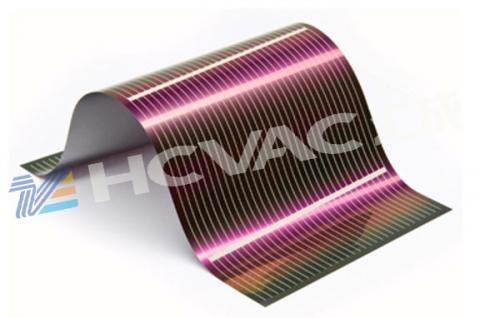

CIGS thin-film photovoltaics: ZnO:Al based contact layers;CuGa and in precursor layer;SiOxNy barrier layers and Mo metal back contact layers

CdTe thin-film photovoltaics: Metal back contact layers based on Al, Cr, Mo, NiV

Organic photovoltaics: Deposition by sputtering and VTE